Fire, UV, and Water

In this section we are discussing what happens when A1 comes in contact with fire, in contact with sunlight (UV) and in contact with water. In the final section we will answer some of the questions related to the behaviour of A1 in an high humidity/water environment.

When you are working on a A1 object which will be placed in an outdoor environment and/or an environment with high humidity we strongly suggest to read this section.

FIRE

![]() 1.0 European classification.

1.0 European classification.

Classification of reaction to fire performance in accordance with EN 13501-1:2002. A1 (Acrylic One) LP01 and A1 Tri-axial Fabric: B-s1,d0

Its reaction to fire behavior is classified : B

The classification to smoke production is : s1 The classification to flaming droplets / particles is : d0

Classification of reaction to fire performance in accordance with EN 13501-1:2007+A1:2009. A1 LP01 and A1 Tri-axial Fabric + sand (25% of mass A1):

A2-s1,d0

2.0 USA fire rating.

Evaluation of the surface burning characteristics of a material identified as A1 in accordance with ASTM E84-15b, standard test method for surface burning characteristics of building materials.

Flame Spread Index (FSI) : 20

Smoke Development Index (SDI) : 15

This “fire test” is made by one of our customers to see for himself how A1 reinforced with triaxial fiber does withstand this blow torch.

See yourselves how the fire stops when the blow torch is removed, showing that the A1 does not burn by itself. Also the lack of smoke development is important as smoke is one of the major factors causing victims during a fire. Finally you will notice that the back of the panel is unaffected.

Be aware that this is only a video for demonstration purposes only. Use our official fire test reports to learn more about the behaviour of A1 during A1.

uv

![]() 4.0 UV has a strong influence on the durability of materials. 20+ year old A1 project in South Africa shows that (coated) A1 will withstand UV influence.

4.0 UV has a strong influence on the durability of materials. 20+ year old A1 project in South Africa shows that (coated) A1 will withstand UV influence.

When an uncoated A1 object is exposed to (intensive) UV the very thin top layer of the A1 object will be affected (erosion) within a few months. This will mainly be noticeable by a change of the colour of the A1 object. After this initial period the erosion by UV will continue but at a very slow rate.

5.0 Adding sand to the A1 object (1 part A1 Liquid, 2 parts A1 Powder and 2 parts Quartz sand) will still result in an initial erosion of a very thin top layer but after this the added sand will almost stop the erosion process of the A1 object caused by UV.

For the best protection we advise applying layers of A1 Sealer PLUS to the A1 object as this layer will act as a barrier between the UV radiation and the A1. When you have used our A1 Sealer we recommend to apply a new layer(s) after 3 years with our A1 Sealer PLUS. For our Sealer PLUS we recommend a new layer(s) after 6 years. Other coating systems can be used as well if they are damp open (KEIM Soldalan) or the A1 object can release its moist at the backside of the A1 objects (for ventilated Cladding systems).

water![]()

6.0 An A1 object placed outside needs to breathe.

A1 attracts moisture and also releases it during dry periods. Therefore, the urgent advice not to disrupt this process by using a non damp open sealing paint or coating. The moisture still present in the A1 is converted into water vapor during warm periods and this can damage the coating system or the A1 top layer. A1 objects that are also not able to ventilate on the inside because of the use of, for example EPS, are extra vulnerable.

Below we will explain what will happen when you place an A1 object in a high humidity environment and how to make sure your A1 objects stays in excellent condition when place in an outside environment.

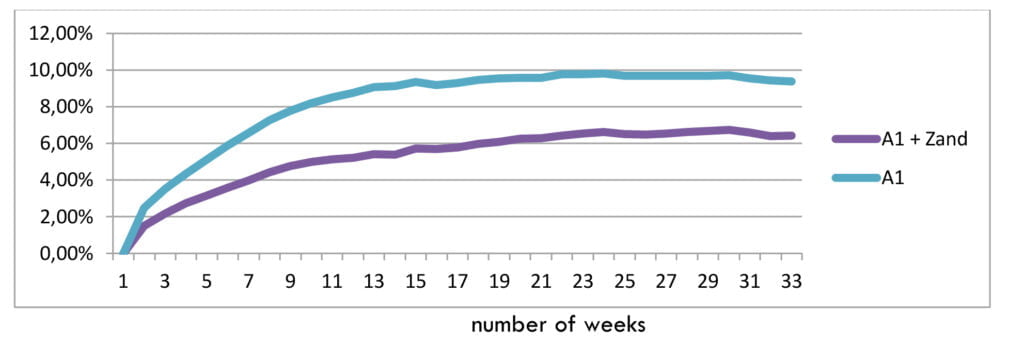

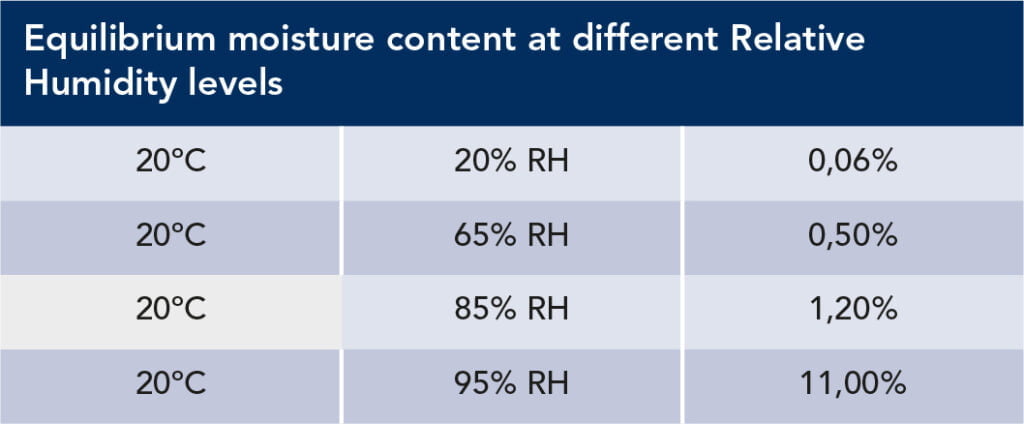

7.0 Similar to many other materials, A1 will attract moist/water at a humidity rate above 90%. As can been seen in graph 1 it will take several weeks at very high humidity level to reach the maximum levels of 10 to 11% water absorption. If we add sand to the A1 (1 part A1 Liquid, 2 parts A1 Powder and 2 parts Quartz Sand) the water absorption is significantly lower.

An A1 object will release its water when placed in an environment with a lower humidity (below 70%) at a high speed as can be seen in graph 2. It only takes a few days to reach the levels at starting point.

Exposure of an A1 object to very high humidity environment is possible for several months without affecting the A1 object. The use of an A1 Sealer PLUS or coating system will extent this period as it acts as a barrier between the humidity and the A1 object.

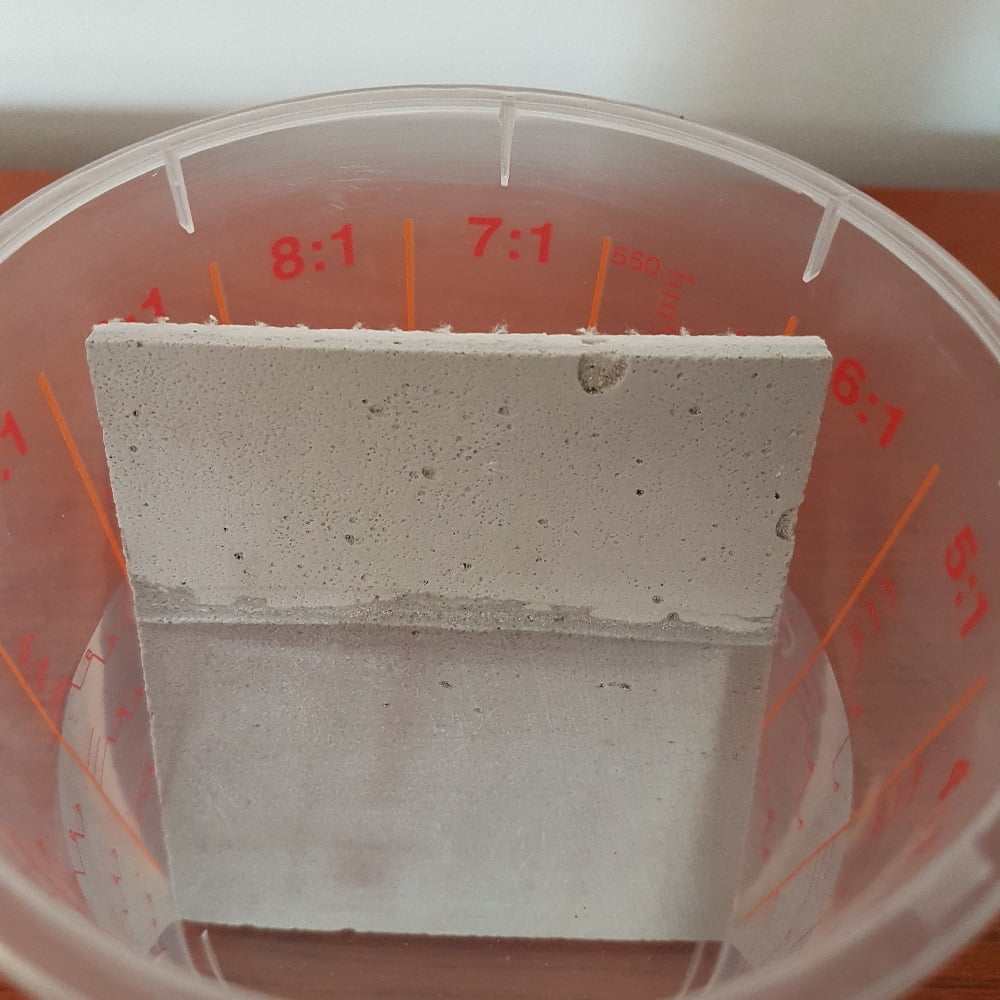

We have also tested A1 objects fully submerged under water and tested the quality of the top layer with the use of a Shore measurement (picture 1 and 2). Based on these tests an A1 object can be fully submerged under water for a period of 2 months without weakening the top layer. After this period the top layer weakens and the A1 will slowly dissolve in the water.

![]() 8.0 Do I have to avoid moisture collection?

8.0 Do I have to avoid moisture collection?

Yes, you do have to avoid moisture collection as the A1 object will absorb the moisture that is collected.

Very occasionally we come across A1 projects where the water can collect in. As long as this place is provided with sufficient protection, it will not be a problem for the A1 for a few days. For a longer period of time, this is something we really do not recommend. Similar to what we sometimes find on construction sites where A1 panels are stored before being mounted with the panels facing outwards with the wrong side up. This gives the rainwater every chance to collect and, because often no coating is applied to the

rear, the water has every chance to penetrate into the A1.

Constructively, this is not a problem for the A1 over a short period, but on the visible side, the places where the moisture has penetrated will soon be visible, even after it has dried. For a shorter period, even some days this will not be a problem but the A1 object needs to have the opportunity to release the moisture/water it has absorbed. If a situation like in the picture above remains for too long the top layer of the A1 will weaken because of the levels of moisture collected.

![]() 9.0 Can A1 be used to protect other materials against weather influences?

9.0 Can A1 be used to protect other materials against weather influences?

Regularly we are asked whether A1 can be used to weatherproof a sculpture made of plaster, clay or concrete blocks.

Unfortunately, this is not recommended as A1 absorbs (to a limited extent) moisture and will transfer this moisture to the material that has to be made weatherproof. These materials eagerly absorb this moisture from the A1 without transferring it back to the A1 in dry conditions to evaporate. This creates spots with a high continuous moisture load that weakens the connection between the A1 and the material it covers. At higher temperatures, the water evaporates or at low temperatures the water freezes. This creates so much pressure between the different layers that the A1 layer loses its bond with the underlying material.

That is why we advise to only use (glass fabric reinforced) A1 or underlying materials that do not absorb moisture.

![]()

Bath Bunny

This A1 object with a polystyrene core is floating in the Rotterdam waters for several years now. The layer of A1 coated onto the polystyrene core is in good condition, excluding the layer of A1 which is fully submerged under water, which has dissolved in the water. The layer of A1 which is directly at the waterline is still fine as it does absorb water in rough conditions but has the opportunity to release this water when exposed to air.

![]()

Totem pole

This totem pole placed in a swimming pool is at the top made of A1 with a foam core. The lower part (50 cm) is made of polyester.

10.0 Use filling materials that do not absorb moisture

A1 is excellent to use in combination with a large number of filling materials. It adheres excellently to, for example, wood, textiles and chicken wire. It is possible to add almost all small ground materials to the A1 mixtures, creating

special shapes in appearance and structure.

For A1 objects that are placed outside, carefully consider beforehand whether this combination of materials also works well here. For example, we know that wood attracts moisture via the A1 and can even expand, causing the A1 layer to crack. Chicken wire will start to rust due to the moisture present in the A1 and this creates traces of rust in the A1. We encountered A1 objects where hydrograins were mixed in the A1 because it gave a nice structure. Subsequently, these hydro grains absorbed so much moisture that the surrounding A1 became soft and the top layer of A1 with hydro grains subsequently separated from the underlying glass fabric reinforced A1 layers.

Only use filling materials that do not absorb moisture or that will not corrode due to the present moisture. We have had good experiences with materials that do not absorb moisture and rust, such as granite, sand, EPS (Styrofoam) and aluminium.

Reinforcement materials and inserts required for mounting can cause problems in outdoor situations when these materials absorb moisture such as wood. Better use aluminium, stainless steel, EPS or pre-produced reinforcement profiles or backs of A1.

11.0 Can we use A1 to build a fish pond or to use it as an object in an aquarium?

That is not possible as A1 will absorb that water for a long period of time and will in these situations not have the possibility of releasing it again.

12.0 Can we use A1 in an aqua parc where the A1 elements will frequently be exposed to water?

The answer to this question depends on the actual situation. To expose an A1 element to water is possible as it only will absorb water at a slow rate. However you need to give the A1 element the opportunity to release this water again, which in many cases will be possible. Especially if the humidity drops below 80% for a longer period, such as during the night.

To protect the A1 element even better you can choose to use a damp closed coating on top. However you need to make sure that the rear of the A1 elements has no or a damp open coating. The moist interaction will in this case take place at the rear of the panel.

So the answer to this question depends very much on the context where the A1 element is placed.

13.0 Is it possible to make a soap holder of A1?

Making a soap holder with A1 is very easy. However using a soap holder made of A1 in your bathroom is not advisable. Normally soap is used about every day in combination with water. After use the soap is returned in a wet condition to the soap holder. As it will be lying on the soap holder for a longer period the water between the soap and the soap holder will be absorbed by the soap holder.

14.0 Make sure residual moisture has disappeared.

During the production process, moisture in the A1 liquid reacts with the A1 powder. A part of the moisture remains behind (residual moisture). Therefore, before an object is placed outside, it is important to make sure that the residual moisture has disappeared from the product. The duration of this depends, among other things, on the construction of the A1 object, the thickness of the laminate, the humidity present and the temperature of the storage location.

Our advice is to give the A1 object the chance to evaporate the residual moisture in a covered area with room temperature for at least 7 days. At that time, the coating can also be applied.

15.0 Avoid horizontal parts.

A1 can withstand rain showers or an environment with a higher moisture load. In a situation where the A1 object is (very) long exposed to moisture, without the chance to dry again regularly, the top layer can become softer and in extreme cases even loosen from the underlying layers.

That is why our advice is to ensure that (rain)water can always drain off the A1 object easily. Provide sufficient slope and avoid horizontal or badly sloping parts in the A1 object.

16.0 Is it possible to make a flower pot of A1?

It is possible to make a flower pot with A1. You can use a silicone mould to cast the A1 into the mould or use a core material like foam in combination with glass fiber to create thicker panels which you can join together to make a larger planter.

As A1 will absorb water we suggest putting a sealer/coating on the inside. This will largely prevent that the water into the soil will be incorporated into the A1.

That’s why we advise not to use A1 to make pots which will only be filled with water.

17.0 Extend the life with a damp open coating system.

Our tests show that A1 objects can be placed outside for a long time with only a limited change on the outside. To extend this period by many extra years, we recommend applying a coating. This coating protects the A1 object because it absorbs the influence of weather conditions. Because A1 is a material that absorbs and releases moisture (breathable material), it is important to ensure that the coating system also has a breathable effect. The A1 Sealer PLUS is suitable for this, but also many wall paints such as KEIM Soldalan.