Support moulds

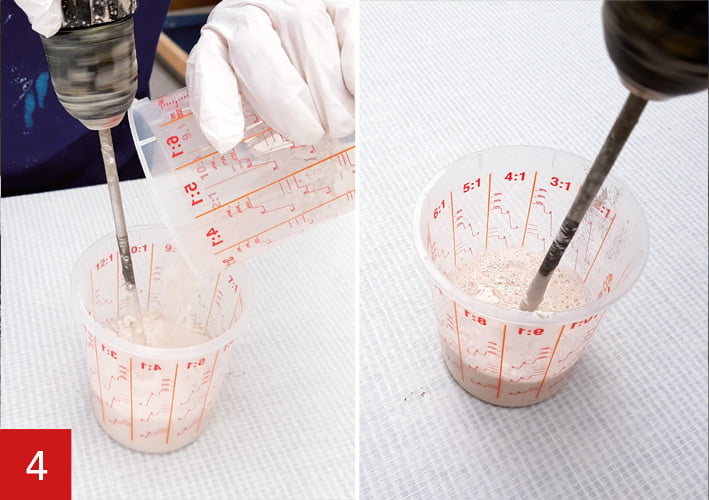

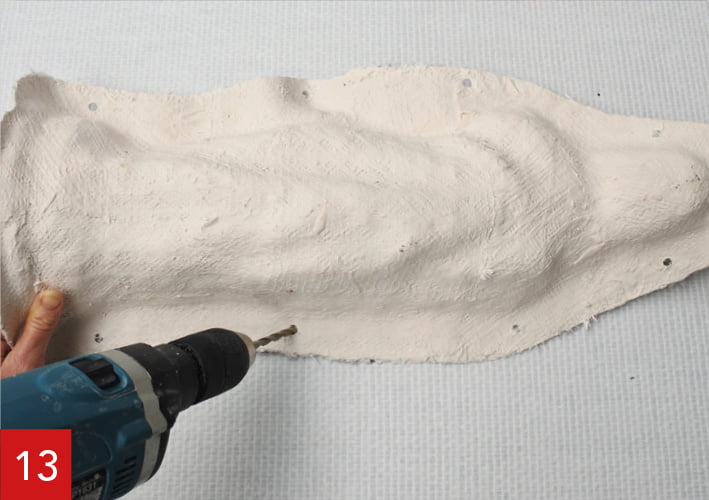

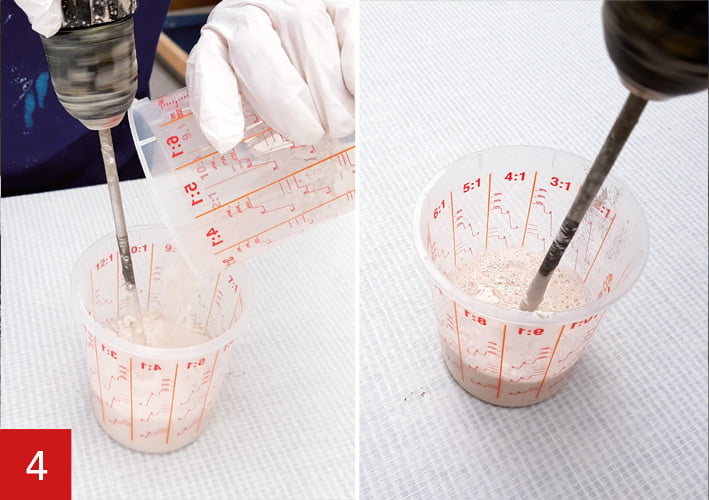

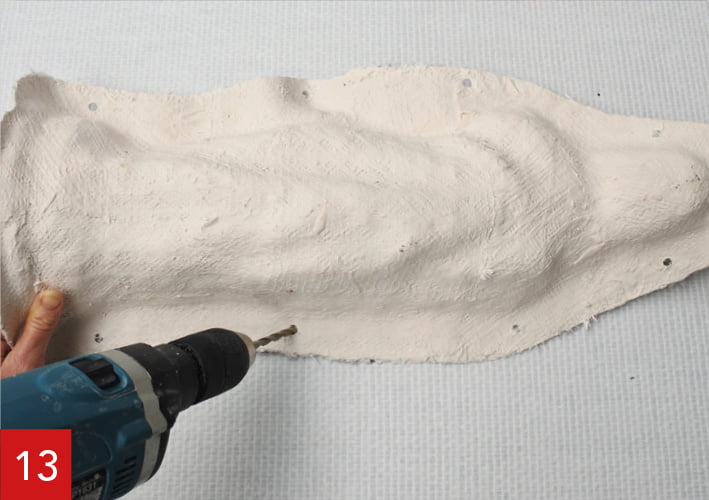

A1 is very suitable for making very strong and also lightweight support moulds, by laminating A1 in combination with A1 Triaxial fibre.

Instruction sheet

A1 is very suitable for making very strong and also lightweight support moulds, by laminating A1 in combination with A1 Triaxial fibre.